'Oi ~ No Ka 'Oi Design

The ‘Oi No Ka ‘Oi Hawaiian Steel Guitar is the result of a conversation with Alan Akaka and a dream, and was introduced just 6 months later at the 2022 AISGC & HSGA Festivals. This series of articles explore the reasons behind and the process of developing the steels: Design, Sound & Tone Production, Strings & Intonation, Signal Chain, Ergonomics, Aesthetics and Realizing the Dream.

Part I: The Process of Design

The process of design for me is very similar whether it’s a piece of furniture, a home, a community, or an instrument. It is logically working through a set of criteria and ideas to achieve a particular goal and, in particular with instruments, involves a lot of back and forth – if I try one thing, does it affect another? That process at the beginning is expansive – it’s exploring all the things that COULD be done – and then reverts to a reductive focus of deciding which things SHOULD be included to find the essence, or cleanest resolution, of the design. No one design of anything can achieve all possible goals … which is why there are many alternatives of everything.

Previously I’d been focusing on acoustic instruments; originally that was inspired by Herb Ohta Sr. and Lyle Ritz at the Maui Ukulele Festival and Slack Key Festivals. I loved both slack and the jazz influences, and in particular on the baritone ʻuke, but couldn’t find an instrument I liked. I have a deep background in furniture building, and all the tools, so I built my own with some generous advice from a luthier from Tasmania. From there it’s been a natural progression into various instruments including acoustic lap guitars – Weissenborn and teardrop.

Those instruments are primarily tuned in Taro Patch open G tuning or similar, and readily adapted from 6 string guitar tabs. But I had become enamored with C6, which is a lovely tuning with the relative Am over C chord, and is useful in other genres such as country and jazz. With 6 strings it’s a close tuning, spanning only an octave and a half from A to E, and I was thinking about building an 8 string for a wider tonal range.

At last January’s Los Angeles Slack Key Festival, I asked Alan Akaka what he thought might be the best tuning for an acoustic 8. Having the 5th (G) on top seemed good to me, with an A on the bottom to have two identical Am7 sets or with a low Bb for the 7th. Alan recommended a wider range with a low C on the bottom, then with a Bb for the seventh.

Accomplishing that successfully in an 8 string acoustic would be rife with conflict as a battle between structure and tone; that’s a high wire act between building the lightest, most responsive instrument and it collapsing under constant string tension – for an 8 string, more than 200 lbs, and for a 10 string 250 lbs – on a fragile soundboard. There is also a limitation on how much acoustic response you can get at the deep end due to the limitations of producing a long wave length on a relatively small body size.

And critically, if you are going to play live, you must have amplification, which with an acoustic instrument is another battle – between tone and feedback. The growth and explosion of popular music in any genre cannot be separated from the ability to amplify good sound for large audiences; professional musicians depend on it for their livelihood.

A NEW BEGINNING

From this single short conversation with Alan, I went away considering taking a different tack: creating a new instrument from the ground up, focusing on sound production from the strings to amplification and eliminating all the middle ground.

The fundamental questions became:

- Since professional players need amplification, and the acoustic guitar is fraught with complications of producing a full range of sound and then amplifying it, why not skip as directly as possible from producing the notes on the strings to the amplified output?

- Can I produce a tone that is equal or superior to that of an acoustic, with a much deeper low end and crystal clear highs?

- Would a steel then be more adaptable to different genres to have a broader appeal?

- Can I devise a single design concept, readily adaptable to 6, 8 and 10 strings, different scale lengths, open to various tuning possibilities, and with a variety of interchangeable pickups and other electronic components to adjust the sound to suit different applications?

This essentially meant designing and building an electric based steel, but approaching it from the back end forwards, focusing on tone from the amplifier through the signal chain, and playability, stripping away the unnecessary to see where I would arrive.

There are steels that originated in the heyday of the 50s and 60s, primarily for country, which can be pretty twangy with a hum prone single coil pickup. There are also newer designs with active electric guitar sounding pickups. The Hawaiian guitar has had a huge and perhaps underappreciated influence on county, blues, jazz and pop/rock music; I was looking for as a natural or organic Hawaiian sound as possible, while at the same time making it as adaptable as possible for other genres while preserving the warm acoustic sound.

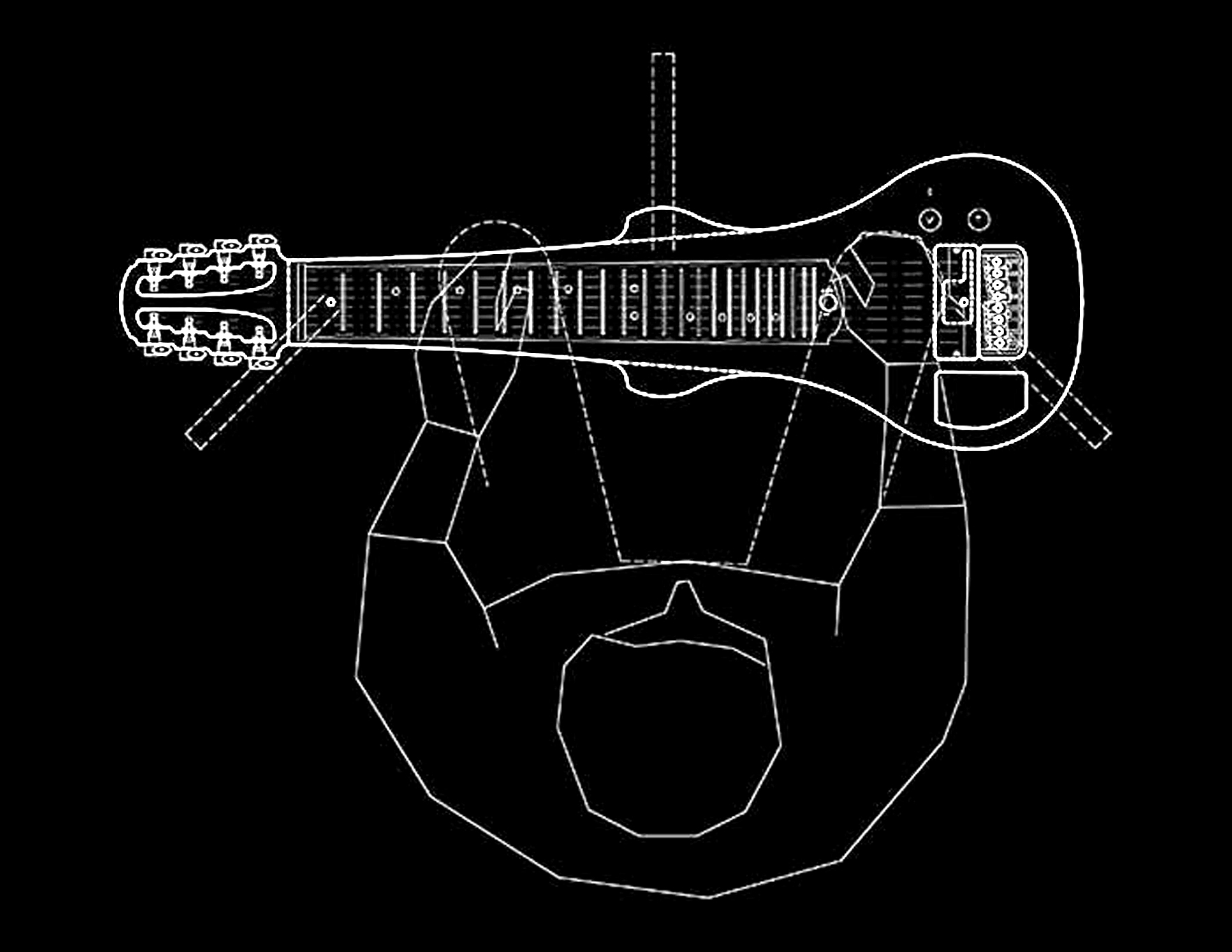

Certainly a lot of ground to cover for one instrument. In addition to satisfying all the fundamental questions, the two aspects to focus on were tone production and the ergonomics of playing position. And as happens when I design, I dream design solutions; frequently when working through a solution, I wake up in the middle of the night with an Ah-Hah moment. That resulted in this drawing, which wound up being pretty close to the final design after going through the rest of the process:

Part II: Sound, Tone Production & Resonance

In order to address sound quality, we have to start with a basic agreement on how we hear sound. A critical notion is that we all hear differently – most of us have lost some portion of the frequency range, and everybody’s unique, so we actually don’t hear the same thing. We don’t know how other people experience any of their senses – we make an assumption that others hear what we hear, or see what we see, but they don’t!

Various genres utilize different sound textures. If an instrument is within a band or group, it has to hold its own place or frequency range to be heard within the group, each instrument having a layer within the overall sound. For instance, a gypsy jazz rhythm guitar intentionally has a constricted tonal range compared to a fingerstyle guitar, as it serves the function of a timekeeper or percussionist in addition to guitar player, and tight sustain.

Finally, and rarely discussed, is that what the player experiences as the sound of an instrument, particularly with acoustic and to a lesser degree but important with an electric, is different from what the audience hears.

AN ACOUSTIC GUITAR’S SOUND

Acoustic guitar players hear a “sound,” but what are they hearing? The guitar sound is comprised of the fundamentals – the open string notes – and the partials – all the harmonics above that – which are produced by a complex relationship of materials. Each note is comprised of many frequencies; if it were a single one it would just be an uninteresting monotone.

“It turns out that ~1500hz is the lowest frequency of sound that can escape the guitar box through the sound hole”. That is note G6 or the second octave above a high G string; therefore ALL the fundamentals on an acoustic guitar are produced by the vibration of the top and back of the instrument, in turn moving the air all around it, and omni-directional.

(Gore & Gilet “Contemporary Acoustic Guitar Design”)

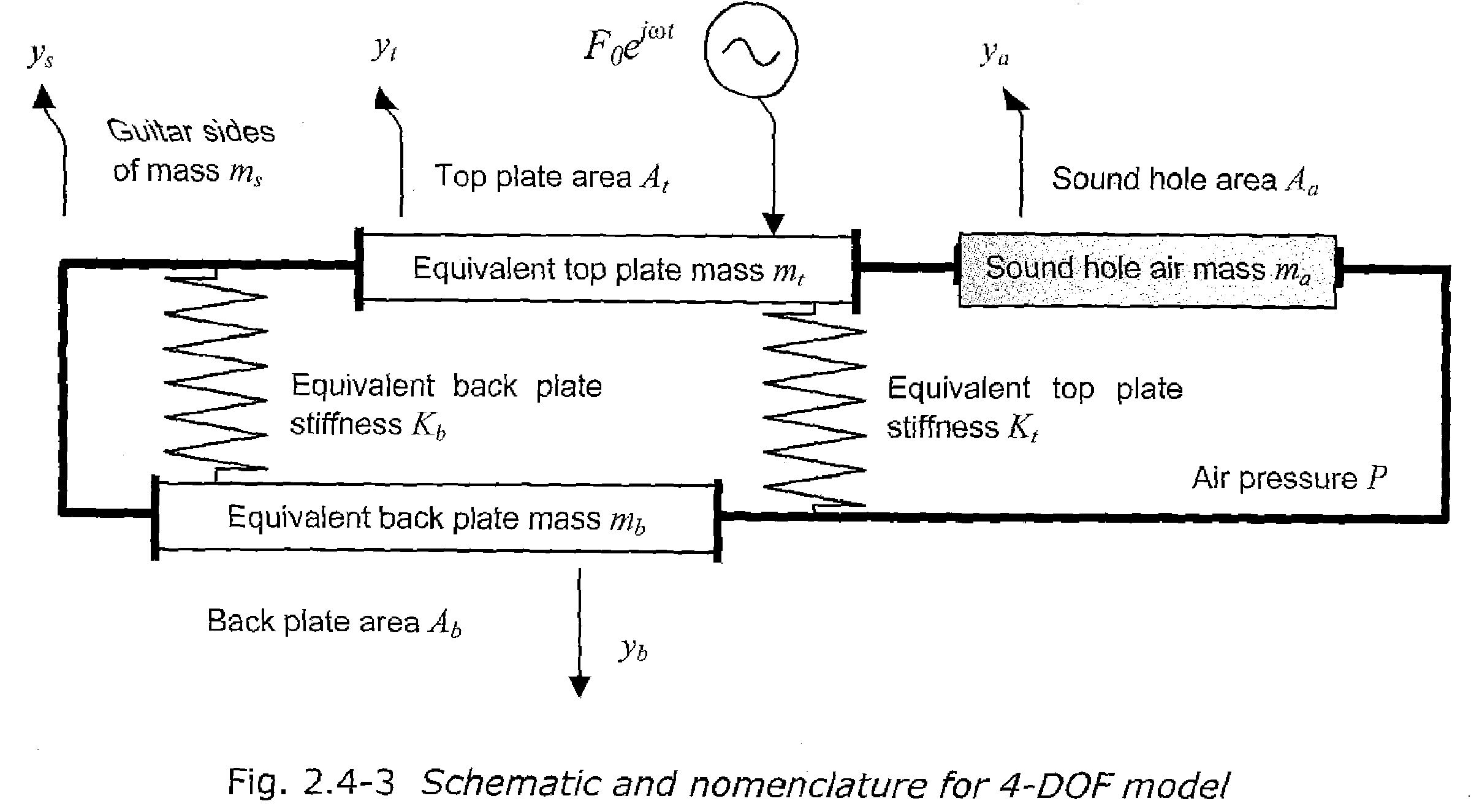

The interrelationship between the top and back – the ”Helmholtz coupling” created by containing the air between them with the sides – is critical as no fundamentals actually come out of the soundhole, making the top and back the creator of all the low sounds.

What is extremely important and makes the guitar sound like a guitar, is the harmonic content, which above G6 escapes via the soundhole and we hear up to 18000 hz or higher with great ears. That is the texture or voice of the instrument. If you put your hand over the soundhole, it mutes the high harmonics, not the lower fundamentals, and changes your perception of tone as it is altering the balance of frequencies.

The acoustic guitarist is hearing a blend of low notes produced by the vibration of the instrument itself in a close or near field and the harmonics above G6 through the soundhole (which with a conventional center hole are pointed away, towards the audience, who hear them differently than the guitarist in a small unamplified setting). They are created by all the strings and everything else that is vibrating.

If the instrument produces too much of one frequency, it is heard as taking away another. So if you need to balance out the sound, you may have to reduce some tones to allow others to shine. This is the interrelationship between the string choice and guitar construction. It is also, in essence, the core of audio engineering, recording and mastering. It’s a complex gumbo!

AN ELECTRIC GUITAR’S SOUND

A pickup in essence is a circuit that is effectively magnetizing the string, turning it into a moving magnet relative to the stationary coil. The tone is controlled by the coil materials, which determine the inductance (in Henries), impedance and resistance (in ohms). As such, it can’t possibly “hear” the tone of the wood. Any marketing that a certain wood sounds a certain way on an electric is confusing the near field tone, which you may hear unplugged, and the amplified signal.

The audience hears the amplified signal which has been altered by the particular environment (room, concert hall, etc.). The player hears some of that reflected back, the same or modified signal through monitors, the near field sound of the instrument vibrating if the volume isn’t too loud, and may feel it through their bones if played on the lap. Then the amp and various electronics offer multiple ways to alter and balance the tonal content.

How all this affects the sound, and what the listener perceives but isn’t necessarily accurately identified as to the cause, leads to a lot of confusion in describing what a certain instrument sounds like, depending on your perspective. When you play an instrument, especially an acoustic in a quiet setting, the near field acoustics have an impact which is not transferred through the air or pickup & amp (the signal chain) to the larger far field. An electric player feels the sound, but again that is not shared by the audience.

BODY MATERIAL

This suggests that the body material is less important for amplified tone production than advertisers would claim, especially for the professional musician under amplification where it overwhelms most if not all of the near field tones you would get at home or on a very small stage. You frequently hear comparisons of the tonal qualities of various woods in terms similar to fine wines – woody, sweet, mellow, overtones, etc. This is stated primarily for acoustics, but also somewhat with electric amplification which can’t possibly be true. While there may be a perception of difference to some subjective degree, they seem to be primarily marketing; the tone of the body material in the overall context of the guitar is too limited a factor when everything else is considered. (However, this clearly does not apply to unamplified acoustic classical instruments such as the violin, which is played close to the ear.)

RESONANCE

This has lead to the overarching goal of producing instruments that have great “resonance”, which is a very distinct concept from “tone”.

“Resonance is an action/reaction equation. When vibrations occur in one location, and then transfer to another location (including the air) through some degree of filtering, this is resonance. Generally speaking, resonance is something considered to occur both in real-time, and depending on the amplitude of the original vibration source (and environmental acoustics), will occur across time after the original vibration occurs. In other words, you play a note, and some filtered element of the original note continues for some duration afterward. This can be reverberation in a room, it can be the decay of an acoustic guitar top still ringing moments after the note is played, and a lot of the way it impacts what we hear and feel is by blending and adding to the original note.” (Frank Falbo)

Resonance applies to our whole auditory world: not only music but the single human voice, a church choir, clapping your hands, or even in the stillness of meditation where there is a prevalent background of resonance, and is inseparable from the environment. It is the presence that is underneath and in addition to the original sound.

Instrumental resonance is dependent on four main components: how it is played (plucked vs. bowed), the sound production of the instrument, the output via the acoustic and electric signal chains, and the environment it is played in.

There are many resonant qualities we might associate with instruments: long vs. short sustain, warm vs. cool tone, complex harmonics vs. dry, full vs. thin, and so on, including the concept of the “voice” of the instrument.

There is no one “best” guitar resonance; there are many depending on the type of music to be played, and the context – for example solo or in a band, rhythm or lead, and the genre. What’s important is that the luthier produce the desired sound intentionally, and that the musician pick or order an appropriate instrument to their style, or perhaps more than one to cover different situations, as one can’t possibly do everything.

The two major materials that Hawaiian guitars have been made from are steel, as with a frypan, and wood. I’m a wood guy, so my comments are specific to that and not to metal, with which I don’t have the expertise.

After the pickup, different materials do determine one of the most fundamental determinants of good sound for the steel guitar in that the two anchor points of the strings must be as solid and stable as possible. The body material and composition, which largely determine the body rigidity, has the primary role in accomplishing this.

Part III: WHY INTONATION MATTERS

The strings are suspended by the nut at the peghead and by the saddle at the pickup end. You can view these components as a little tension structure:

The scale is the distance from the start of the string at the nut to the 12th fret, times two, which is slightly less than the total distance from nut to saddle. It is chosen to accommodate different instrument body lengths, the player’s arm length (and muscle memory), and string manufacturing. If the scale is set incorrectly, it throws off the tuning.

Steel strings are made of steel (or bronze); wound strings have an additional nickel or phosphor bronze wrapping over the same core. String makers build their guitar strings to match the scale and tonal output of the vast majority of the guitar market, which are designed around the 25.4” Martin scale.

The tension of strings is critical to their performance. Steel strings behave in a certain manner according to their ideal designed “speaking length”. You can easily calculate the theoretical tensions for any string based on the unit weight, core size, scale and frequency. For an acoustic you can only work outside that parameter by a maximum of about 6% and might be able to get away with as short a scale as about 24” using standard strings of the appropriate weight to create the tension you want, but that’s the limit.

After that, to maintain tension, the strings just get too heavy and unresponsive to vibrate correctly. As the scale gets longer, the strings get thinner to maintain the same tension, or deflection, under your fingers or bar pressure.

Electric guitars use the pickup to sense the string vibration and offer more latitude for string sizing as they may be lighter, but there is still a limit and they have to be calculated according to the scale.

ACTION

Action is the distance the string bends until it stops. In this case of a guitar, that’s to the fretboard. An electric guitar is played lightly and the action is very small. An acoustic is played harder to create volume and the action is larger to let the strings vibrate. Steel strings are stiffer with more tension than classical, which require more action.

On a steel guitar the action is the amount of deflection, which is dependent on the tension of the strings and how hard you press down with the bar.

I use 23” for shorter scale lap guitars and 24¼” for longer legged models. 25½” as a super long scale is possible for those accustomed to playing an acoustic Weissenborn, but many lap players prefer to minimize the steel body overhang off their legs.

COMPENSATION

As the strings on any instrument are fretted or barred, they are being stretched, which raises the note. Depending on the amount of bend, extra length or “compensation” is added to all the strings so as you play higher, it maintains the correct relative pitch, and “sweetens” the sound from flat.

At 25# of string tension, the string deflection under bar pressure on a steel is about .05” and results in about 1/16” of overall compensation, making the overall distance from the nut to saddle a bit longer than the “scale”. Lighter strings have less tension and more deflection, requiring more intonation.

Since there aren’t any frets, and the bar can be placed anywhere, it doesnʻt matter much if you are playing single notes, in the sense that you are playing by ear regardless. In addition, many players use vibrato which both sweetens the sound and masks an off tone.

If you are using your markers to visually guide your playing it matters a bit more, and as you get higher, you are going to have to manually compensate. This is not critical until you get to the next aspect: intonation.

INTONATION & STEEL SADDLE DESIGN

Intonation in steel playing is simply the accuracy of pitch, or “in tune”, which as you know isn’t all that easy, and is critical. For our purposes we’ll define intonation in guitar building as the individual difference in compensation between each string. This occurs because solid strings or the cores of wound strings stretch more as the diameter increases; thicker strings require more compensation. The cores of wound strings, which determine their tensions, start out close to the treble strings, so after the lowest solid string, the wound intonation begins at close to the start of the solids, and again gets larger. This applies to most fretted or unfretted steel stringed instruments. (Noting that classical strings require very little compensation or intonation due to different physical characteristics of the strings.)

A well-made custom acoustic steel string guitar typically has a Z-shaped or lightning bolt saddle, which shifts at the change between the solid and wound strings. Electric guitars and basses frequently have a “hard tail” bridge with individually adjustable saddles for each string.

Some maintain that because a steel has no hard frets, intonation isn’t required, but that is incorrect according to the science. The same compensation and intonation principles apply to a steel guitar; just think of it as upside down from a fretted guitar; as with “bending” a note, bar pressure causes the string frequency to rise.

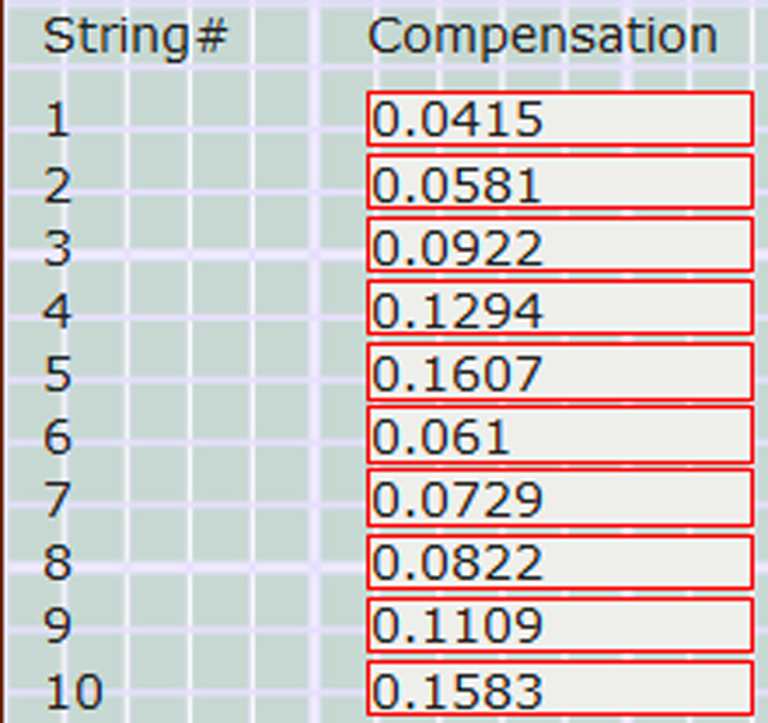

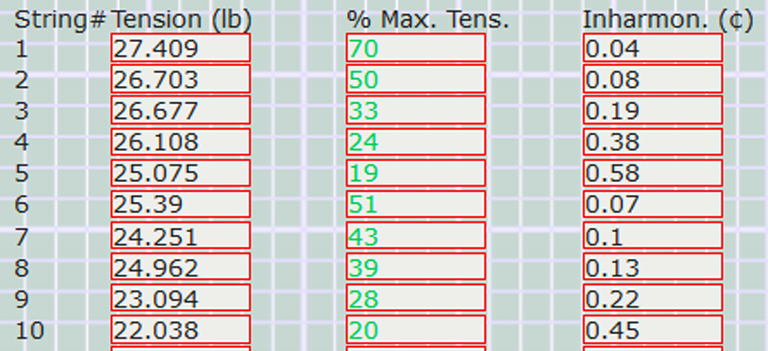

Note that #1 to 5 require progressively longer intonation, and then it repeats but slightly differently for #6 to 10. Due to the physics of strings, as they get lower they get larger and results in different tensions; it just isn’t possible to have exactly the same tension for all strings at all frequencies. Larger strings are subject to more inharmony in the third column below, which is critical:

In this example, the #5 solid string would require the most intonation and would have the most inharmony at over ½ of a cent (1/100 of a tone). That doesn’t sound like much, but the first chart requires about .16 inch of intonation. If not, you have to adjust your bar by .08 inch at the 12th marker, a bit over 1/16, to be in tune, and confirms steel guitarist John Ely’s position that anything over an 022 solid string is too unstable. Once this was calculated, #5 switched to a wound string, which shifted the jump in the Z saddle from 5 solid & 5 wound to 4 solid & 6 wound.

If you are playing single notes you can adjust by ear, but if you are playing a chord of some sort, your bar has to incline to an angle to make up for the lack of intonation. But it can’t because the intonations are unequal between string types, and most significant is the shift point between solid and wound strings which would show the most off tuning if you happened to be playing both strings, such as an A and F# in A6. An intonated saddle allows placing the bar consistently perpendicular to the strings. Note on the chart that it’s not exactly a linear equation, but an average for each section is quite close and helps to play in tune. The ‘Oi 5/16” thick compensated & intonated C13 saddle for the 10 string steel with 4 solid and 6 wound strings looks like this:

The greater the frequency range of tuning, as with C13 from C2 to G4, the more important this is. A tighter range as with E13 from B2 to G#4 results in shallower angles, with the same jog between solid and wound strings.

Here’s a quick experiment anyone can do on their own: tune your upper string to the right note, in C6 it’s usually either E or G, with a digital tuner. Now find the same exact note, an octave higher, at the 12th marker and note where you are. If you’re not exactly above the marker, you are not compensated. You can double check that with a tape measure: the length from the nut to the crown of the saddle should be a little more than twice the length from the nut to the 12th marker. If it’s exactly double, it’s uncompensated.

That really doesn’t matter so much as you are finding the notes by ear with your digital assistant. Just note the relative position of the bar to the marker. Now do the same on the lowest string. If your octave has moved towards the nut, and that is likely if your saddle goes straight across, perpendicular to the strings, you are not intonated. You can also check to see if there is a difference at the 12th marker between the thickest solid string and thinnest wound string.

TUNINGS

Taking into account tuning and scales, the appropriate calculations resulted in the following steel guitar tuning chart, using one set of strings for each scale (23” & 24¼”) to maintain tension, to offer some different possibilities with 6, 8 and 10 string setups. Each of the teachers noted below utilizes different tunings in their material based on C or A; all of the tunings can be accessed with the 10 string with only a 1/2 step retuning of half or fewer of the strings. The transition between the solids and wounds – the Z breakpoint – always occurs below A regardless of the instrument:

Now you know why an intonated saddle matters, and why the ‘Oi No Ka ‘Oi is made only with an intonated brass saddle. It is more accurate in pitch and is mo’ betta.

PART IV: THE SIGNAL CHAIN

The rest of the electronic signal chain includes the headstock with tuning machines and nut; body construction; the tail with saddle and string anchor; and electronics with pickup, controls, cord, amp and speaker. Although they are discussed as distinct entities, they need to be matched as well as possible as all are part of a chain in which a weak link can counteract everything else.

Fundamentally, we don’t want to lose any string energy due to heat loss through soft materials or deflection. Strings must be anchored with as little horizontal movement as possible to transfer as much energy to the pickup as possible, and not bleed off into the body or poorly fitting parts.

THE HEADSTOCK

Tuning Machines: The most important factor with tuning machines is to have a rigid post. One that deflects is a great way for poor tuning capability, slippage and energy loss. I now exclusively use Gotoh tuners as others just haven’t been worth it for me, although there are good alternatives out there, and they are made to order for me in a really nice Cosmo Black color.

Machine Angle: My reference point is acoustic guitars, but having a standard peghead, designed for a vertical guitar, isn’t ergonomically friendly on a horizontal steel. My headstock design was based on an upside down version of the traditional slotted classical guitar peghead which used posts that anchored on both sides of the slot to minimize deflection. In order to use modern tuners, I modified this idea to use stepped sides to maintain perpendicular tension on the tuner post, leaving a minimum of ½” of stock between slots in order to inlay a carbon fiber bar for structural support. Strings which are exactly straight through is theoretically superior, but impossible with a wood headstock as the center mass is critical to the structure. It was only after designing it that I saw the same approach in most pedal steels.

The passive section of the string between the tuning machine and nut is not well understood. What is known is that if the section is very short, it inhibits accurate tuning in that short stiff string sections are much more sensitive to tune. A longer passive section allows for easier and more accurate tuning, effectively creating a higher gear ratio.

String Tree: It doesn’t seem to be necessary for each pair of strings to have the same angle, but if upward torque on the furthest point of the headstock causes problems, especially with a long 10 string, a string tree can be used to lower the strings for tension that is more parallel to the body structure.

Nut: Soft nut and saddle materials are a real killer for tone. I CNC mine in brass; as they say, it rings like a bell! Additionally, they are wider than normal with a curved approach for solid contact and a nice clean release for the string to ring true.

THE BODY

With my traditionally-influenced acoustic aesthetic inclination, I wanted a narrower Weissenborn style neck rather than the blocky steels of the 50s, but needed to be able guarantee the body forever. As mentioned at the beginning, the design process controls the final product; during this process I stumbled across a critical discovery… Our original concept was this:

We know we have to maintain that tension or everything goes poorly. If the body bends, the strings loose tension and deflect:

If the nut or saddle rotate or bend, the strings loose tension and deflect:

So what I did is trade the weight of a thicker body for the weight of two truss rods in to create a counter to the constant string tension:

The truss rods are inlaid unparalled into the lower half of the body before laminating on the top. Also note that graphite bars are inlaid into the peghead to prevent is from splitting or warping. These give great stability to a wood product that otherwise is prone to issues with changing humidity or temperature, and will never warp as it can be adjusted to perfectly flat.

Voila! No deflection, no added weight. This has made all the difference in not only the long term stability of the instrument but resulted in an instrument that is sprung like a cat, just waiting to jump, and creates a very warm near field sound for the player. It’s quite cool and I am applying that discovery to electric basses and guitars.

THE TAIL

The Saddle: As previously noted, the saddle in milled from brass to match the nut tone, but is thicker to provide good contact and minimize breakage of the highest string. In addition, due to the high string tension of up to 250#, a brass stop is installed to prevent the wood grain of the bridge from crushing.

String Angle: As with the nut, downward force is necessary to maintain good contact and solid tone. Frequently one sees the strings break at close to a 90 degree angle, diving directly downward through the bridge, with no passive string length. This is a misunderstanding of force vectors; I believe that the angle and string length should roughly match the nut to provide the same ease and accuracy of tuning.

String Anchor: Strings that mount to a bracket of some sort on the top of the instrument are subject to deflection if too light, or screws loosening over time. I prefer to bring the strings through the body for maximum contact. The string ferrule wrap has to compress into a washer during the first few tunings, but after that it’s bombproof.

ELECTRONICS

Pickups are very interesting and critical. The original laps used single coil pickups which have a great 50s sound, but can be quite hot and are prone to hum or other artifacts. Humbuckers were developed to counter that and are a good choice. Some builders use active pickups with a battery, but I found the tone to be too modern/electric guitar, without depth, and primarily use George L’s pedal steel pickups which are nicely organic sounding. They are passive with no battery to maintain but have plenty of output, and have no moving parts to fail. Although they have been discontinued, I have enough stock to do my entire buildout with 4 different versions (10-1, SS, TW and PF) ranging from very warm Hawaiian to a crisper country sound. I also offer SteelTronics custom wound humbuckers that are close in sound to traditional single coils, but smoother and without hum or noise.

The make of the volume and tone potentiometers are more critical than you might think. I started with the most well-known guitar pots, but they were too stiff for a rapid wah-wah slide with the volume or tone control – so I switched to Bourns audio pots which are not only very smooth, but have a better frequency adjustment and are surprisingly much clearer in tone. I install a treble bleed on the volume control so that treble isn’t lost as you turn down the volume (which is “normal”) and a two stage tone switch between fine grained or quick adjustments.

(Design by Mike Auman)

A skinny little cord has more resistance, and if too long dampens the signal, making it darker. A thicker braided cord is always preferred.

Amp choices are complicated, with tube and solid state options, and have different settings with very different tones, effects and voices. They are a critical part of your sound.

For my legged (console) steels, I offer a leg tray with a very nice small Quilter amp head – they are as close tonally to a tube amp that you can get with terrific emulations of the Fender ’57 and ’65 tone. It has a speaker out to my stage monitors (which are also useful as a home speaker), and can additionally line out to a larger amp or PA for gigs. They also have line in for a backing track and headphone out. The controls are close on hand to be able to shape your sound well beyond the standard pickup tone control.

The final link of the chain is what you actually hear – the speaker itself. I am building a series of small monitors, dovetailed in mango to match the No Ka ‘Oi and sized to carry onto a plane. I will compare 10” and 12” speakers from Eminence and Celestion side by side with professional players in a variety of genres, and post those findings in the next article, which will conclude with some professional player thoughts on Finding Your Tone.

All the components in the signal chain contribute to your final tonal output, and should be carefully chosen to create the sound you want.

Part V: ADDITIONAL CONSIDERATIONS TO FINDING YOUR TONE

ERGONOMICS & PLAYING POSITION

My music background is keyboards, so I like sitting at the instrument on legs. I also busted my neck a long time ago, so looking down onto my lap gets uncomfortable quickly. To keep good ergonomics with your elbows a bit above your wrists, the legs need to be the right length so that the steel is just barely above the lap. It winds up being a bit further away from you. For myself and the others who have tried them, it’s enough to make a BIG difference. And it’s just sitting there all time wanting to be played. Or I can switch over to the keyboard or bass without having to muck around with the steel. Or plug in an additional instrument to the amp.

I designed and made custom flush fittings with very light carbon fiber legs, and flight cases sized for air travel, so everything is organized and secure. All those aspects were critical to me in developing the instrument to be as versatile as possible. It also had to be light without sacrificing longevity, so it’s easy to haul around and equally suited for those who prefer to play on the lap.

Photo: Mike Wittmer

AESTHETICS

The look, although important in the end to many, doesn’t particularly interest me by itself – it is subservient to the tone and playability of the instrument. “Form follows function” is a bit of a worn expression; I think of the two as intertwined. Basically if an instrument doesn’t play well, have good ergonomics and sound great (which is a relative concept to the genre, setting or application), it’s not going to be used much and is a failure of purpose.

Steve Jobs said "Design is not just what it looks like and feels like. Design is how it works."

The goals drove the design of the instrument, which then met the fundamental criteria. From there, I lean towards shapes that refer to or are influenced by traditional acoustic instruments, as that’s what I’ve mostly built and the music I listen to. In this case it’s a modified Weissenborn shape, with Maui hooks on the cutaways, and a teardrop relief in the top, then reimagined into a smaller profile which is just large enough to accommodate the components for full range of strings, scales and amplified tone. The actual shape of a wood steel doesn’t affect the sound if built well, but does feel nice to the hands and to hold. And the grain of mango is as beautiful as any.

IT’S ALL ABOUT THE MUSIC

The bottom line is that if you have an instrument that you love to hold and listen to, you’ll play more and better. I received this note recently:

“Once I finally started playing, I can’t seem to stop. I practice every day, and while I know I have a long way to go (before it ever sounds presentable to another person), I am enjoying it tremendously.

I can really tell this is a quality instrument, and I doubt I would have stayed with it with something inferior. I really appreciate the resonance of each note (when I hit them) and just zone out into a state of happiness. The hand-feel of the neck, the craftsmanship, the beauty of the wood are all such a pleasure to experience again and again.

Thank you thank you. Obviously, I think of you often, with gratitude.”

There is no greater reward to the luthier than to not only hear great music made by their instrument, but hear about the peaceful and rewarding state of mind that it brings to the player.

This series of articles has addressed some of the factors in designing a steel guitar. But ultimately, tone is in the hands of the player – a great one can make a decent guitar sound fantastic, but no amount of great hardware will make a great player. I will now turn this discussion over to those who really know about playing and finding your tone…

From Alan Akaka:

“Here are some tips for achieving the “Hawaiian” tone:

Of course the pickup and amp makes a difference. I prefer a pickup with nice fat lows which is a reason why I mentioned using the George Lʻs on the ʻOi steels. My kumu Jerry Byrd would set his treble, mids and bass on the Fender Twin to 1, 1, 10 respectively. On my Princeton Reverb I set the treble to 1 and bass to 10 to get similar results. The main thing is to find a tone that is comfortable to the playerʻs ear so no matter which amp is used tweak the settings accordingly. One more thing, placing the amp on a table top, cart, floor, close to a wall or in a corner can make a huge difference.

When playing my steel, I add a little more pressure on the bar which thickens the tone and actually contributes to a more vibrant “ping” in harmonics. Also, for a richer tone pick midway between the bar and bridge.”

For the Alan Akaka School of Hawaiian Music, visit https://kekulamele.com/

From a 2018 interview with Mike Neer:

“There are certain sacrifices you have to make in learning to play an instrument. I don’t know anybody who was just born with the ability to play. It takes a lot of hard work. I have devoted a lot of energy to it and made the decision to just play steel; I couldn’t see going back and forth from guitar to steel anymore. I didn’t want to just pick up the steel guitar to play a couple of songs. I wanted it to be an instrument that, at will, I could play anything that I wanted to play. In order to do that, I needed to put the guitar aside.

I think one of the hardest things to do is to put aside, to some degree, what you already know and learn how to approach the instrument. If you were suddenly left to play guitar with just one finger, you might have to rethink the way that you look at harmony. You have to keep thinking: reduction. That process took me a lot of years to realize. You think you’re making progress and you’re nailing all this really cool stuff but it sounds like you’re really struggling to make it happen. With steel guitar, it should have a sense of ease to it.

One of the things that I figured I needed to do was to simplify it; look at harmony in a new way in terms of upper extensions and triads and to start building from there. I think there’s a little bit of progression going on [in my playing] now. I can feel it. I feel pretty excited about it, actually.

Once you’re on the path to discover your own voice, you find the sounds that you like. Sometimes we listen to other players and hear something we want to avoid. So I really did make a conscious effort to not be a very “slidey” player. I listened and decided that I didn’t really like sliding too much unless it was for an exaggerated effect.

I use less of the gliss effect than some other players because I thought it took away from the right-hand articulation. I wanted to make the melodic lines more articulate. That was the goal. Now that I’ve gotten to the point where I can control that more, I’m bringing more of the sound of sliding into my playing and hopefully, I’ll sound like I have control over that as well.”

Visit Mike Neer’s webpage: http://www.lapsteelin.com/ And his recording “Steelonius” is fabulous!

From John Ely’s “Hawaiian Steel Guitar Web”

“Learning the steel guitar is a labor of love and, incidentally, a lifetime endeavor! …Steel guitar is without a doubt one of the hardest instruments you can take up. But the rewards are great if you can stick to it. You'll have a rare gift that no one can take away from you, as Jerry Byrd used to say.”

“There are many types of bars that have been designed for steel guitar. Most are unusable! I recommend strongly that you purchase a quality "bullet" shaped bar that is 3/4 inch in diameter. The bullet end should be smoothly rounded and the bar should be long enough to cover all of the strings when you place the bar at the 12th fret. For a typical 6-string or 8-string steel guitar, a bar that is 2 ¾ or 2 7/8 inches long should work. You don't want a bar that is too long—for example, one that sticks out more than a half inch when you place it on the 12th fret. A bar that is too thick or too long will be difficult to maneuver properly.”

“Tuning Mechanics: We call it "tuning up" for a reason - always start with the string below your target pitch and slowly raise the string up to your desired pitch. If you start with the string higher than your target pitch and then tune down to your note, you're going to have problems. Because of the metal-on-metal construction of tuning gears there is inherent "slack" in the system. If you tune downward instead of upward, the tuning gears could slip a little resulting in a flat note, and this could happen in the middle of a steel solo! Always tune upward to remove the slack in the tuning gears.”

“Tuning Systems: Okay, now for the fun part. Here's a boiled down version that I hope makes sense to you. For quite a while western music has been based on Equal Temperament—a tuning system based on a 440 A—an invention designed to make all keys sound similar harmonically. Before that, musical instruments were tuned via natural harmonics, the so called 'Just' tuning method, which had a very rich sound but made playing in different keys difficult or impossible. Some instruments, notably the piano, can even be "stretch" tuned to compensate for how the human ear perceives notes in different registers. Ouch! How does steel guitar play into all this?

Steel guitarists generally follow one of the tuning systems just mentioned above. Let's break it down to three schools of thought:

- 440 Tuning - tuning all your strings to an electronic tuner based on A 440 (Equal Temperament).

- Harmonic or Just Tuning - tuning to the upper harmonics generated by your tuning's primary note (C for a C6th, E for an E7th, etc.). When you tune by this method half the strings are flat to 440 tuning.

- Adjusted Tuning - This is like Harmonic/Just tuning but all the pitches are raised up by a small amount so that the average of all pitches is closer to 440.”

To continue, read MUCH more at https://hawaiiansteel.com/learning/tuning_up.php

WHAT’S IN A NAME?

‘Oi is heard in the expression Maui No Ka ‘Oi, meaning “Maui is the best.” I think of “the best” as in “awesome” or “Da kine”; I called my instruments ‘Oi as a reflection of doing my best to make the best I can.

“No Ka ‘Oi” is an adjective preceded by a noun; “Oi No Ka ‘Oi” is a play on words, roughly meaning “the best of the best,” also referring to the quality of the native mango that I use. I harvested a 150-year-old dying tree from my land on Maui’s north shore two decades ago, and have used the wood for furniture, doors, cabinets and instruments, culling it out until I was left with the best of the curliest grain, which I’m using for this limited run of steels, until it’s all gone – with just a couple of dozen left. Even though this particular design is new, this project including lots of acoustic Weissenborns, teardrops, ukuleles, guitar and bases will have taken 25 years from beginning to end of this run!